Over the past years, the recovery, recycling and reuse of wastewater has become a major trend as well as an inescapable need globally. Amidst the steadily increasing environmental concerns, scarcity of freshwater and stringent regulations, industries are in constant search of the best method of wastewater treatment. Though Zero Liquid Discharge (ZLD) methods have been in use at industrial sites for quite some time now, there have been multiple challenges.

Challenges for ZLD at industrial sites

1. The conventional methods of ZLD using thermal evaporators, (though effective) are a challenge in terms of the economic and energy aspect. This method is highly energy consuming and requires huge capital investment.

2. Innovative and customized ZLD solutions for different types of industries developing effective high recovery systems capturing different types of effluent composition has been a challenge.

3. Ideal operating conditions for ZLD, including temperature, pressure, scaling, and susceptibility to foul need close monitoring.

4. Choosing the right kind of evaporator effects for a system with several effects is a challenge.

5. Effluent characteristics along with related corrosion and temperature issues and challenges of material compatibility have been leading to high operating costs for ZLD treatments.

What the future holds for Zero Liquid Discharge?

New developments and innovations in the ZLD methods are not only promising solutions for industrial sites like textile, pharmaceuticals, electronics and minerals etc. but also becoming a global favourite for industrial water treatment. The emerging membrane-based ZLD technology has been cutting the cost as well as beating the energy requirement resulting in effective treatment of Condensate Polishing Unit.

#1. To minimise the price of ZLD systems, more dependable, higher recovery MLD (Minimal Liquid Discharge) processes must be achieved first, which requires advanced RO (Reverse Osmosis) elements designed to handle difficult brine fluids.

#2. After the RO step, three membrane based processes namely, ED (Electrodialysis), FO (Forward Osmosis), and MD (Membrane Distillation) have proved to be effective alternative ZLD technologies to brine concentrators for further concentration. These procedures generate brine, which is used as a feed for the crystallizer or evaporation pond.

Analysis of the benefits, drawbacks, and energy requirements of these processes show that the final result is perfect for regulatory compliances and hence outweighs the economic constraints. These technologies are advanced methods that combine heat and membrane based techniques in some cases, such as thermolytic FO and MD. Although heat energy is used in these processes, the main separating elements of these technologies are membranes.

Zero Liquid Discharge Plant Technology

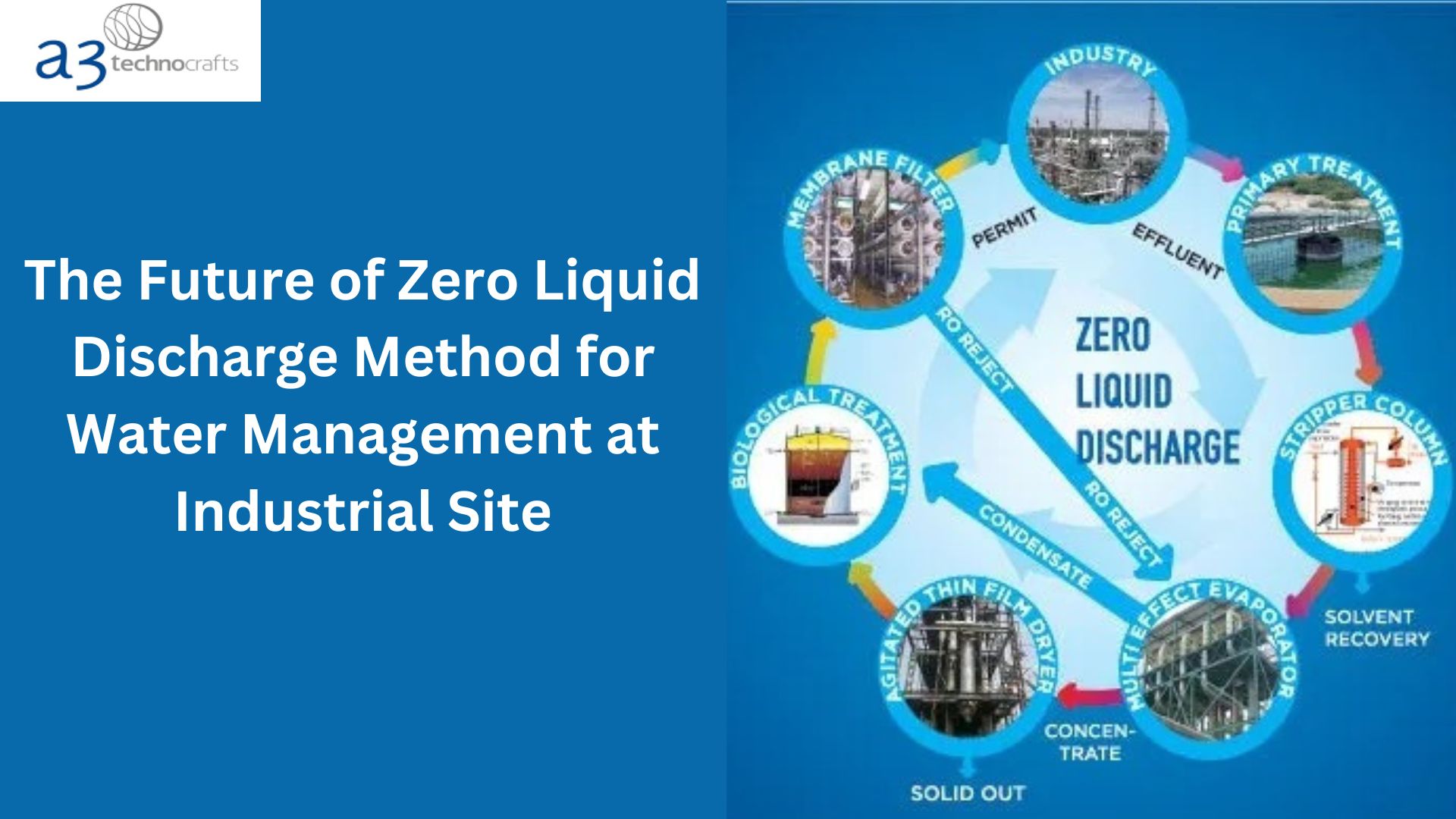

Zero liquid discharge (ZLD) technology typically involves a combination of several treatment processes, depending on the composition of the wastewater and the desired level of treatment. Here are some of the common steps involved in a ZLD plant:

1. Pre-treatment: In this step, the wastewater is screened and pre-treated to remove large solids and debris, and to adjust the pH and temperature of the wastewater to optimize subsequent treatment processes.

2. Reverse osmosis (RO): The wastewater is then treated using an RO system, which uses a semi-permeable membrane to remove dissolved solids, organic compounds, and other contaminants from the water. The permeate, or treated water, is then collected and sent for further treatment or reuse.

3. Brine concentration: The concentrate, or brine, that is left behind from the RO process is then sent to a brine concentrator, where the water is evaporated and the remaining salts and solids are concentrated and separated.

4.Crystallization: The concentrated brine is then sent to a crystallizer, where the remaining salts and solids are further concentrated and crystallized, producing a solid waste stream.

5. Solids dewatering: The solid waste stream is then sent to a dewatering system, such as a filter press or centrifuge, to remove any remaining moisture and produce dry solid waste that can be disposed of.

From the environmental sustainability point of view and compliance requirements for industrial sites, Zero Liquid Discharge Plant is one of the best methods to adopt. ZLD has a tremendous deal of potential to reduce water pollution and increase water supply, but its practicality depends on striking a balance between the advantages of ZLD, energy consumption, and initial as well as operating expenses. To get the best out of this amazing innovation, the best technologist needs to be in charge to ensure appropriate installation and proper management. A3 Techno Crafts is a leading technologist working with various site based customised ZLD plants across industries. Technologists like A3 Techno Crafts, perform accurate analysis of the generated effluents and other crucial factors for a particular site and find the best possible solution. Both energy consumption and costs are minimised with proper research before installation combined with the use of methods equipped with advanced innovations.