Sewage Treatment Plants (STP)

Sewage Treatment Plants (STP)

A3 Technocrafts Sewage Treatment Plants

At A3 Technocrafts, we specialize in providing high-quality Sewage Treatment Plants (STP) tailored to meet the unique needs of businesses, hotels, residential complexes, and municipalities. Our comprehensive solutions ensure efficient and eco-friendly management of sewage waste water treatment, promoting a sustainable future. With years of experience in the industry, we focus on creating environmentally friendly, efficient, and cost-effective solutions for sewage management.

Sewage Treatment Plant Company

As a trusted sewage treatment plant company, we understand the importance of sustainable waste management solutions. Our team of experts works closely with clients to design, install, and maintain sewage treatment plants that align with their specific requirements. Whether it's a small-scale residential setup or a large-scale commercial facility, we offer customized solutions that ensure maximum efficiency and longevity.

Our sewage treatment plants are designed for various applications, including residential, commercial, industrial, and municipal uses. With our advanced technologies, we ensure that wastewater is treated efficiently, reducing pollution and promoting sustainability. Each plant is tailored to meet the individual needs of our clients, ensuring optimal performance and reliability.

Sewage waste water treatment is a critical process for maintaining clean and safe water supplies. At A3 Technocrafts, we focus on advanced methods for effective treatment of sewage waste water, ensuring that the output meets the highest standards of quality and safety. Our systems are designed to manage large volumes of waste while minimizing environmental impact.

Sewer Treatment Plant Cost

One of the key considerations for businesses and institutions looking for sewage treatment solutions is the cost of sewer treatment plants. At A3 Technocrafts, we provide competitive pricing for our sewage treatment plants without compromising on quality. Our transparent pricing approach ensures that our clients receive the best value for their investment. At A3 Technocrafts, we offer a wide range of solutions to meet diverse budgets while providing optimal performance. Our expert team provides detailed cost estimates to help clients make informed decisions regarding their sewage treatment needs.

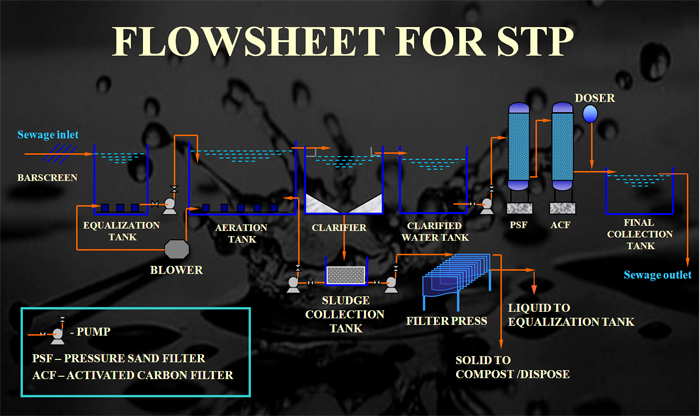

We provide Sewage Treatment Plant that are designed and manufactured using Activated Sludge Process (ASP) technology. The water treated using our plant can also be used for flushing and washing. We also design plants using other advanced technologies such as SAFF, MBBR, MBR, UASB technology and Sequential Batch Reactor (SBR). These technologies are discussed below:

Submerged Aerobic Fixed Film Reactor (SAFF)

Submerged Aerobic Fixed Film Reactor (SAFF) is a cost-effective method of waste water treatment and sewage sanitation that is primarily used in residential and commercial complexes. This technology primarily has on the three stages that are Primary Settlement, Secondary Treatment and Final Settlement / Clarification.

In the wastewater industry, SAFF Technology is seen as the simple and cost effective method of commercial and residential sewage sanitation / waste water treatment, particularly for small to medium sized treatment plants where available land is limited, and where full time operational manning would be uneconomical. A well designed Submerged Aerated Filter plant has no moving parts within its process zones, any serviceable items will be positioned to access easily without disrupting the ongoing treatment.

Submerged Aerated Fixed Films (SAFF) Technology

Submerged Aerated Fixed Films (SAFF) technology is a process used to reduce the organic loading of residential and commercial sewage / waste water, and in doing so will reduce the Biological Oxygen Demand (BOD) and a significant quantity of Suspended Solids (SS) which if otherwise untreated would contaminate river and sea outfalls, in other words it is used to substantially improve effluent discharge quality.

As with traditional sewage treatment, Submerged Aerated Fixed Films Technology too uses three stages of dealing with commercial and residential sewage / waste water.

1. Primary Settlement: Where larger solids settle into the bottom of the primary tank and are removed periodically as sludge, and where other buoyant material which floats upwards is to be removed usually by a scraping/screening method.

2. Secondary Treatment: Where the biodegradable Organic Matter is degraded by the biomass on the SAFF media.

3. Final Settlement / Clarification: Where degraded solids are settled out of the biological treated effluent.

The Submerged Aerobic Fixed Film (SAFF) process uses support media to retain an active biomass to reduce the influent BOD Levels. Tubular diffusers are used with the SAFF media giving a good air dispersal and low level of blockage due to growth of biological film.

SAFF reactor is a type of aerobic attached growth treatment process. Small foot print area, stable process, lesser sludge production and modular installations are the key features of SAFF process. Essentially SAFF system is a hybrid reactor where attached growth and suspended growth activity takes place simultaneously.

This technology utilizes an aerobic fixed film process that is a combination submerged attached growth and activated sludge processes.

Advantages :

1. No sludge re-circulation is required to maintain MLSS as in the case of conventional aeration system.

2. Can be designed to any size to deal with larger flow and loads.

3. Fine bubble diffused aeration used generally reduces the energy requirements as compared to surface aerators.

4. Modular design allows easy installation.

5. The tank does not need to be drained for access to the diffusers or media.

6. SAFF system takes higher shock loads without reducing the plant performance because of large quantity of Bio mass available in the reactor.

7. SAFF system takes higher shock loads without reducing the plant performance because of large quantity of Bio mass available inside the reactor.

8. SAFF supports low sludge generation, low Odour and low visual impact.

9. Solids Retention Time (SRT) of can vary based on influent flow without negative process impact.

10. Modular expandability.

11. Less susceptible to upsets due to flow variations.

12. Simple, yet sophisticated.

13. Maintenance requirements are simple.

MBBR Sewage Treatment Plant

Moving Bed Biofilm Reactor (MBBR) STP is a simple and reliable method of treating wastewater. Due to simple operations and easy manageability, it is better than the conventional methods. MBBR uses a cluster of polyethylene bio film carriers that move randomly in the aerated basin containing wastewater. Since each carrier offers an effective surface area to cater the autotrophic and heterotrophic bacteria, this system is useful for a high-density population of bacteria. High degrees of reliability and ease of operation are assured by the MBBR system.

Our MBBR sewage treatment plant is ideal for removing physical, chemical and biological impurities from the wastewater produced by the kitchen, toilet or industries. We offer a world-class solution that is economical, hassle-free and multipurpose. Whether you choose MBBR treatment or Underground sewage treatment plant, it can be installed easily in a small area. It is ideal for small and medium level usage also because of lower installation, operation and maintenance costs.

MBBR Based Package Sewage Treatment Plant

Packaged sewage treatment plant offers a packaged, ready-to-use system, which is an integration of subsystems such as screening, aeration, equalization of the water flow, sludge digestion, and disinfection of effluent impurities. Since it is a fully assembled system, they are easy to install and use. Made from high-quality reinforced carbon steel, the package sewage treatment plant is made for long-lasting performance. We make sure that only high-strength material and the interior and exterior surfaces are coated with an industry-class epoxy coating. It makes it ideal for wastewater treatment.

We have a team of experts who can offer installation and maintenance support for it. The versatile system, be it package treatment or underground sewage treatment offered by us is ideal for industries, hotels, hospitals, residential colonies, and small and medium industries. We make sure that the treated water passes quality parameters defined by authorities.

Salient features:

1. Superior finish

2. Rugged construction

3. Easy to install

4. Corrosion resistance

MBBR Sewage Treatment Plant

MBBR technology is a combination of attached and suspended growth technologies. Under this process, the media remains suspended in the reactor and offers additional surfaces for the microbes to grow. This in turn maximizes the growth of microbes in a given volume of aeration tank as compared to the conventional aeration without the media. The Bio-Film grows on the bio media surface and moves along with the water inside the reactor chamber creating the biomass. The efficiency of this biomass in reducing the organic load in waste water is a result of successful functioning of MBBR system. Treatment plants are upgraded to increase BOD and nutrient removal capacity from the waste water by enhancing the utilization of existing reactor's capacity. Existing activated sludge plants can be upgraded to achieve nitrogen and phosphorus removal as well. The upgrade to IFAS or MBBR often consists of simply adding carriers and screens to existing basins that upgrades the current plants in a cost-effective and timely manner without major civil engineering and land requirements. PLC based control system optimize IFAS/MBBR process performance by minimizing energy and chemical costs. By selecting innovative MBBR solutions, municipalities can cope with evolving regulation, aging infrastructure and growing population. Industrial plants can meet the strictest regulatory requirements for waste water discharge to the environment or to municipal collection systems, and address typical challenges such as variable inflow, seasonal peaks and high organic loads.

SEQUENCING BATCH REACTOR (SBR)

SBR is new technology for the treatment of domestic and industrial wastewaters.

The SBR can treat wide range of domestic and industrial wastewaters, at flow ranging from few thousand liters to millions of liters per day.

The SBR process can treat any wastewater that can be treated by activated sludge process including anoxic/oxic systems, aerated lagoons, extended aeration processes, trickling filters, rotating biological contactors (RBCS) and oxidation ditches.

Like other biological effluent treatment processes SBR works by developing mixed culture of bacteria (biomass) which is effective for removal of BOD, COD and nutrients commonly found in wastewater.

The SBR is true batch reactor treatment mode, which does not allow wastewater to enter the reactor during react, settle decant phases.

SBR has unique ability to acts as equalization tank, aeration tank and clarifier within single reactor. For large quantities of wastewater flow (more than 500 cubic meters /day) two or more reactors are utilize in predetermined sequence of operation. Each reactor maintains its own treatment regime and all phases of treatment occur in each reactor. Feathers of SBR can be explain as follows-

Tolerate variable hydraulic loads - Mixed liquor suspended solids cannot be washed away by hydraulic surge since effluent withdrawal is typically accomplished in separate phase following termination of flow to each reactor.

Tolerate variable organic loads - Each influent (wastewater input) liquid batch is diluted with previous cycle reactor content.

Controls filamentous growth - Filamentous microorganisms are control by creating anoxic conditions during fill phase.

Provide ideal conditions for settling - Since there is no flow to the reactor during settling and no mechanical sludge collection device "stirring" provided ideal conditions for settling.

Benefits of SBR -

It is true reactor treatment system and able to provide consistent effluent quality to desired limits.

SBR is designed to minimize operation and maintenance cost all equipment's accessible from side the plant eliminating the need to dewater. As -

■ Floating aerators

■ Submersible mixers

■ Effluent pumps

Return Activated sludge piping is eliminated.

Lower Installation costs- Maximum all operation required in effluent treatment are carried out in a single reactor it eliminates need of separate structure for each unit operation this generally result in to lower construction and installation cost.

Lowest electrical operating cost- Electricity consumption per Kg BOD destroyed is around 1.1 KW as compare to other processes (1.7 KW with conventional activated sludge process).

APPLICATIONS -

Domestic Applications -

Municipal

Resorts

Institutions

Industrial Applications -

Chemical/ Petrochemical

Leachate

Food

Tobacco

Paper & Pulp

Dairy

Textile

OCPSF( organic chemicals, plastics ,Synthetics and Fibers)Sugar consumption per Kg BOD destroyed is around 1.1 KW as compare to other processes (1.7 KW with conventional activated sludge process).

MBR STP

The Membrane Bio Reactor Technology is the most advanced development in the field of biological treatment of waste water that recycles in smaller footprint and under stringent discharge norms. The MBR technology combines the skills of the membrane specialists and the biological treatment engineers to deliver integrated treatment solutions with firm process guarantees such as BOD and TSS less than 5 mg/l and also removal of nutrients (nitrogen & phosphorous), coliforms.

Under this process, hollow fiber membranes are introduced to mixed liquor to separate treated effluent from mixed liquor. Membrane being the absolute physical barriers ensures complete removal of suspended impurities. MBR applications include retrofits of existing systems as well as installation of new systems, for both meeting the most stringent discharge norms and reuse. Treated waste water from MBR can be even reused for cooling tower make-up, to generate high purity water through Reverse Osmosis and other non-potable applications.

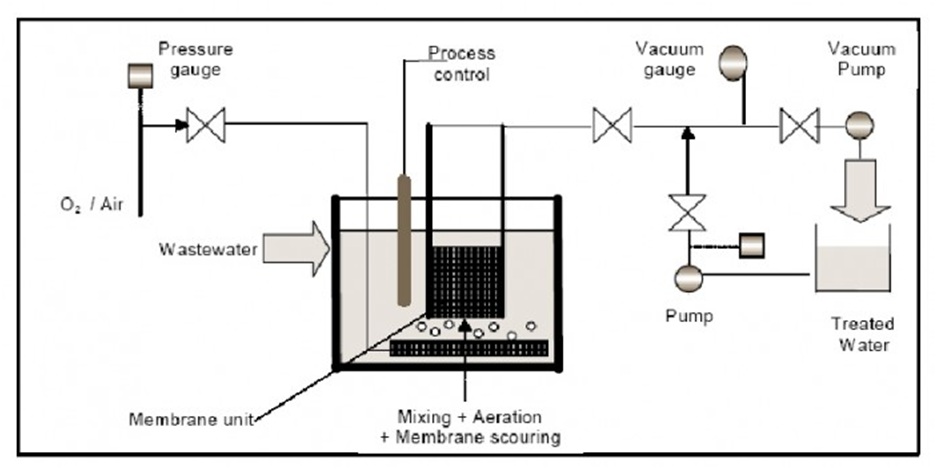

This process can help environment protection by treating waste water and making it suitable for variety of application and thus conserve precious drinking water. Biological system designed for MBR process operates at higher MLVSS concentration with higher sludge retention time and thus it produces a low quantum of biological sludge which in turn reduces the sludge dewatering cost. Biological process fluid (mixed liquor) is pumped to the Membrane Operating System ("MOS"). The mixed liquor is introduced to membrane, along with air, evenly across the bottom of the tank through a unique two-phase jet system. This mixed liquor fills the membrane tank and flows upward through the membrane sub-modules, creating cross-flow dynamics across the membrane surface.

This cross-flow continuously scours the membrane surface and prevents solid dehydration at the membrane surface. Applying a low-pressure vacuum to the inside of the membrane fiber pulls water through the membranes and pumps the filtered water to the next process step. Solids, including organics, bacteria, and most viruses, are rejected by the membrane system and are retained in the mixed liquor, which overflows the MOS back to the aeration tank. The Membrane Operating System is an assembly with integral membrane modules arranged in rack assemblies, inserted into the membrane tank. MOS Mixed Liquor Distribution & Recirculation Jets are designed to distribute the air scour and mixed liquor flow evenly across the membrane sub-modules.

This feature eliminates potential polarization (concentration) of suspended solids around the membrane fibers which could be main cause for the failure and damage of individual fibers thus sub-modules. Additionally, this feature provides even distribution of mixed liquor solids to each membrane unit, to ensure critically that all membranes see the same process conditions. The return recirculation of mixed liquor ensures influent comes in intimate contact with the concentrated biomass, offering better organism selection and added flexibility in the anoxic cycle for advanced nitrogen removal, when required. This same jet system also acts as an integral part of the membrane cleaning system, providing an efficient scouring of the membranes with chlorine cleaning solution.

The integrated cleaning system allows the sub-modules to be quickly cleaned in place. Additionally, the clean and efficient procedure eliminates the need for membrane removal from process tanks that can damage membranes and present risks to plant operators. Relaxation, Maintenance and in situ CIP are exclusive features of this MBR Process to ensure consistent water quality and complete membrane life. The entire operation is PLC controlled.

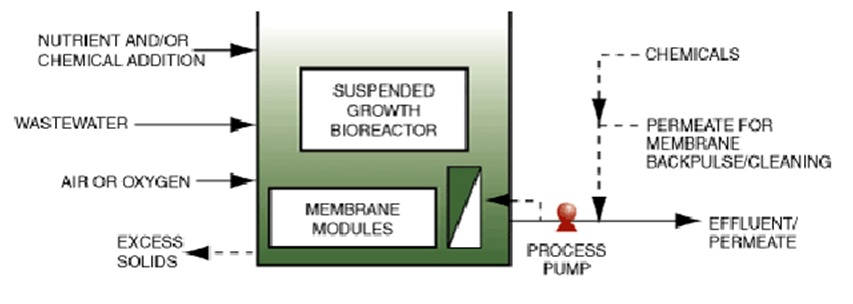

The term membrane bioreactor (MBR) defines a combination of an activated sludge process and WW separation by means of membranes. The MBR process was introduced in the late 1960s, as soon as commercial scale ultra filtration (UF) and micro filtration (MF) membranes were available. The original process has combined the use of an activated sludge bioreactor with a cross flow membrane filtration loop, see Figure 1. The flat sheet membranes used in this process were polymeric and featured pore sizes ranging from 0.003 to 0.01 μm.

Figure 2. Immersed Systems

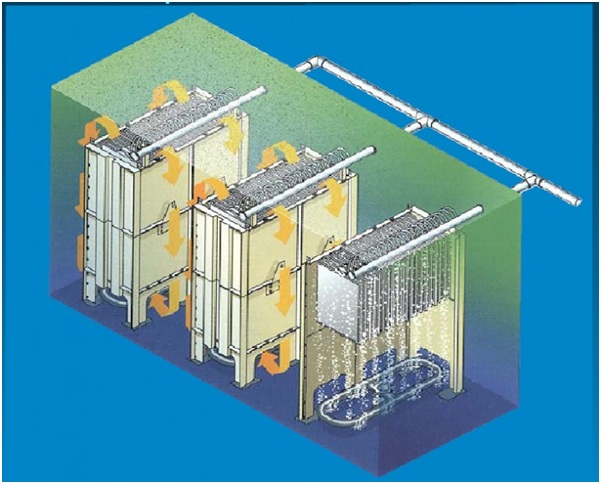

The breakthrough for the MBR came in 1989 with the idea to submerge the membranes in the bioreactor. Until then, MBRs were designed with the separation device located external to the reactor (side stream MBR) and relied on high trans-membrane pressure (TMP) to maintain filtration. See Figure 2, with the membrane directly immersed into the bioreactor, submerged MBR systems are usually preferred to sides stream configuration, especially for domestic wastewater treatment. The submerged configuration relies on coarse bubble aeration to produce mixing and limit fouling. In submerged configurations, aeration is considered as one of the major parameter on process performances both hydraulic and biological. Aeration maintains solids in suspension, scours the membrane surface and provides oxygen to the biomass, leading to a better biodegradability and cell synthesis. This led to a further development of MBR system. A sample configuration of a developed process is shown in figure 3a and Figure 3b shows the water circulation of three submerged modules with perspective view of the modules depicting components inside.

Figure 3b. Submerged Modules.

The popularity of MBR technology lies in following advantages: (over conventional processes)

Most important aspect of MBR technology is production of very high quality effluent consistently.

Compliance with International stringent discharge norms.

Complete independent control of HRT (Hydraulic Retention Time) and SRT (Sludge Retention Time), which allow more complete reduction of COD, and improved stability of processes such as nitrification.

Reduced Sludge Production

Process intensification through high Biomass concentration with MLSS (Mixed Liquor Suspended Solids) over 8000 - 10000 ppm.

Ability to treat high strength wastewater.

Lower footprint than Conventional Activated Sludge Process, since Clarifier/Filters are eliminated.

Reduction in Post disinfection requirements.

Due to above advantages & recent technical innovations and significant cost reductions the applicability of MBR technology in municipal wastewater treatment has sharply increased in Europe, America, Middle East & China. MBR system is now widely used in industrial applications equally. Large MBR systems are normally built with Hollow Fiber or Tubular membranes & smaller installations prefer Flat Sheet membranes.

Figure 3a. Sample MBR Process

Residential development projects

Commercial projects

Mining camps and other remote installations

Emergency response

Military installations

Sports facilities

Recreation parks

Schools

Shopping centers

Office parks