Effluent Treatment Plants(ETP)

A3 Technocrafts: Leading Effluent Treatment Plant Manufacturers in India When it comes to addressing water pollution and safeguarding the environment, Effluent Treatment Plants (ETP) play a crucial role. These plants are designed to treat industrial wastewater, ensuring it meets environmental regulations before being discharged. A3 Technocrafts stands as one of the most reliable and efficient effluent treatment plant manufacturers in India, delivering state-of-the-art solutions tailored to diverse industries.

Why Choose Effluent Treatment Plants?

Industries such as textiles, pharmaceuticals, chemicals, and food processing generate wastewater that contains harmful pollutants. Without proper treatment, this wastewater can harm ecosystems and pose health risks. Effluent Treatment Plants are engineered to eliminate contaminants, recycle water, and reduce environmental impact.

A3 Technocrafts understands the specific needs of industries and provides solutions that are efficient, cost-effective, and eco-friendly. As experienced effluent treatment plant manufacturers, the company ensures that its products meet international standards while addressing local environmental concerns.

Features of A3 Technocrafts' Effluent Treatment Plants

Customizable Designs

A3 Technocrafts offers ETP tailored to the unique needs of each industry. Whether dealing with high levels of organic waste or complex chemical pollutants, the company provides solutions that ensure maximum efficiency.

Advanced Technology

Equipped with cutting-edge technologies, A3 Technocrafts’ ETP guarantee optimal performance. From sedimentation and filtration to advanced chemical treatments, these plants effectively handle diverse types of effluent.

Energy Efficiency

Recognizing the importance of sustainability, A3 Technocrafts prioritizes energy-efficient designs. This helps industries minimize operational costs while adhering to environmental guidelines.

Compliance with Regulations

As leading effluent treatment plant manufacturers in India, A3 Technocrafts ensures its systems comply with stringent environmental standards. This guarantees that treated water is safe for discharge or reuse.

Durable and Low Maintenance

Built with high-quality materials, A3 Technocrafts’ ETPs are designed for long-lasting performance and minimal maintenance, reducing downtime for industries.

Applications of Effluent Treatment Plants

The versatility of Effluent Treatment Plants makes them indispensable across various industries. Some of the key sectors benefiting from these systems include:

Textile and Dyeing: Treating dye-laden water to prevent contamination of natural water bodies.

Pharmaceuticals: Eliminating hazardous chemicals to ensure safe disposal.

Food and Beverage: Managing organic waste to maintain hygiene standards.

Chemical Processing: Neutralizing toxic substances for safe effluent discharge. A3 Technocrafts excels in catering to these industries, solidifying its reputation as one of the top effluent treatment plant manufacturers.

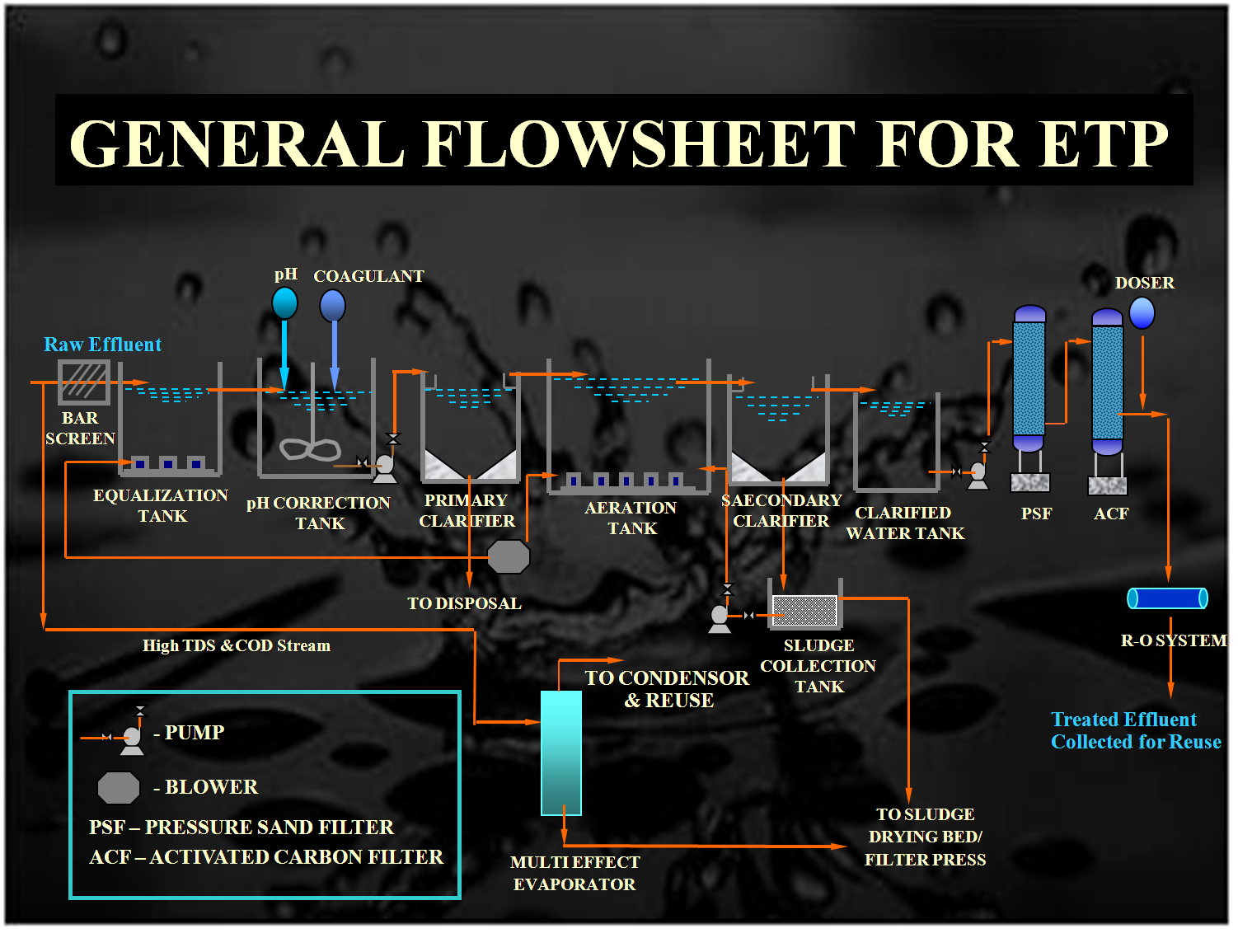

The Process of Effluent Treatment

Effluent treatment involves multiple stages to ensure comprehensive cleaning. Here’s how A3 Technocrafts designs its ETP for maximum effectiveness:

Preliminary Treatment

Screening for the removal of large solids and debris.

Oil and grease separation using specialized mechanisms.

Primary Treatment

Sedimentation to settle suspended solids.

Neutralization of pH levels to stabilize wastewater.

Secondary Treatment

Biological processes such as aeration to degrade organic pollutants.

Use of activated sludge systems for effective cleaning.

Tertiary Treatment

Advanced filtration methods to remove remaining impurities.

Disinfection to eliminate harmful pathogens.

Sludge Handling

Proper treatment and disposal of sludge generated during the process.

By integrating these stages seamlessly, A3 Technocrafts ensures that its Effluent Treatment Plants deliver reliable performance, meeting the specific demands of industries.

Why A3 Technocrafts Stands Out

In the competitive market of effluent treatment plant manufacturers in India, A3 Technocrafts has carved a niche with its unwavering commitment to quality and customer satisfaction. Here’s what sets the company apart:

Proper Expertise:

With years of experience in designing and manufacturing ETP, the company has built a strong reputation for reliability.

Innovation:

A3 Technocrafts continuously updates its technology to offer the most advanced solutions.

Customer Support:

The company provides end-to-end assistance, from consultation to installation and maintenance.

Affordability:

Offering competitive pricing without compromising on quality makes A3 Technocrafts a preferred choice.

Environmental Benefits of Effluent Treatment Plants

Investing in Effluent Treatment Plants is not just a regulatory requirement but also a step towards environmental conservation. These systems:

Prevent water pollution by treating industrial waste effectively.

Enable water recycling, reducing the demand for freshwater resources.

Minimize the release of harmful chemicals into ecosystems.

By partnering with trusted effluent treatment plant manufacturers like A3 Technocrafts, industries can contribute to sustainable development while ensuring compliance with environmental laws.

For industries seeking reliable and efficient solutions, A3 Technocrafts stands as one of the premier effluent treatment plant manufacturers in India. With a focus on innovation, quality, and environmental responsibility, the company’s Effluent Treatment Plants are designed to meet the highest standards. Whether you’re looking to upgrade your wastewater treatment system or install a new one, A3 Technocrafts offers the expertise and technology to meet your needs.