Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic Flowmeters

Ultrasonic flowmeters use sound waves to determine the velocity of a fluid flowing in a pipe. At no flow conditions, the frequencies of an ultrasonic wave transmitted into a pipe and its reflections from the fluid are the same. Under flowing conditions, the frequency of the reflected wave is different due to the Doppler effect. When the fluid moves faster, the frequency shift increases linearly. The transmitter processes signals from the transmitted wave and its reflections to determine the flow rate.

Transit time ultrasonic flowmeters send and receive ultrasonic waves between transducers in both the upstream and downstream directions in the pipe. At no flow conditions, it takes the same time to travel upstream and downstream between the transducers. Under flowing conditions, the upstream wave will travel slower and take more time than the (faster) downstream wave. When the fluid moves faster, the difference between the upstream and downstream times increases. The transmitter processes upstream and downstream times to determine the flow rate. They represent about 12% of all flowmeters sold.

Plusses and Minuses

This technology can be very accurate and is used for custody transfer (meaning accounting accurately for an expensive fluid) of natural gas and petroleum liquids. High turndown (can read low as a percentage of the full scale or top reading), handles high pressures, is repeatable (consistent), handles extreme temperatures, can be used clamped to the outside of a pipe without penetration, is low maintenance, highly reliable and self –diagnosing. Disadvantages can include high cost, sensitivity to stray process vibrations, problems with pipe diameter change due to buildup and clamp-on units have lower accuracy.

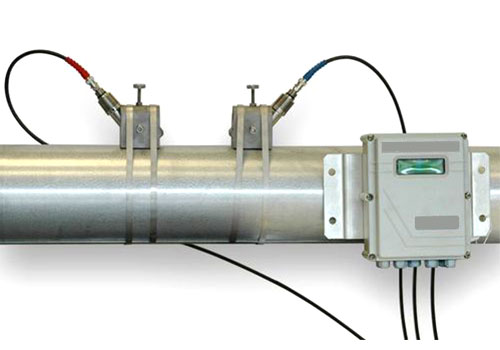

Ultrasonic flowmeters do not obstruct flow so they can be applied to sanitary, corrosive and abrasive liquids. Some ultrasonic flowmeters use clamp-on transducers that can be mounted external to the pipe and do not have any wetted parts. Temporary flow measurements can be made using portable ultrasonic flowmeters with clamp-on transducers. Clamp-on transducers are especially useful when piping cannot be disturbed, such as in power and nuclear industry applications. In addition, clamp-on transducers can be used to measure flow without regard to materials of construction, corrosion, and abrasion issues. However attractive, the use of clamp-on transducers introduces additional ultrasonic interfaces that can affect the reliability and performance of these flowmeters. In particular, if not properly applied and maintained, attenuation of the ultrasonic signal can occur at the interfaces between the clamp-on transducers and the outside pipe walls, and between the inside pipe walls and the fluid Ultrasonic flowmeters are available in sizes to 72 inches and larger.

Our Locations

A3 Techno Crafts Pvt. Ltd.

RO: A-502, Panchsheel, Plot No. 9, Sector - 10, Dwarka, New Delhi - 110075

AO: Plot 228, 2nd floor, Sector 19, Dwarka, New Delhi-110075 India

Processing Unit:

Chhochhi Industrial Area, Samalkha, Distt. jhajjar, Hayrana 124107

9810131831

info@a3technocrafts.com

Representative offices:

Dubai:,

Bhawan Tower, Al Nahda 1, Duabi, UAE

Nigeria:

69, Admiralty Way, Phase 1, Opp Electro Mart, Lagos, Nigeria

Canada:

7199 Wrigley Court, Mississauga. L5W0C8, Canada

United Kingdom:

35 Sherwood Gardens, Isle of Dogs, E14 9GA, London, United Kingdom

Australia:

96 Meurants Lane, Glenwoods NSW 2768, Australia

USA:

6352 Inglewood Drive, Pleasanton CA 94588, San Francisco, USA

Germany:

Reichenschwand, Germany