Zero Liquid Discharge (ZLD) as the name suggests is a process designed to achieve zero liquid status in the waste generated or a method to eliminate waste liquid completely. Main driving force behind this is to minimize water wastage and maximize its usage through recycling. This proves beneficial for the environment and economy by saving gallons of Zero Liquid Discharge Plant.

Industrial wastewater contains a lot of harmful biodegradable or non-biodegradable substances which are unfit to be discharged into water bodies. Harmful effluents and discharges from the industries are threatening the environment. We all know water is very scarce in many parts of the world. Saving water is a growing concern for which various measures like regulating the way water is used have been taken around the world. ZLD uses advanced technologies in water treatment plants to purify wastewater.

Design of a Zero Liquid Discharge Plant (ZLD) plant

ZLD plant is designed and customized according to the site where it is needed. It is mostly needed for industries which depend a lot on water for their operation and process. There are various factors that needed to be thought of before a ZLD can be installed. The byproducts of ZLD operation are liquid and solids, out of which water is used again for various processes and the solid part is discarded in landfill or treated further to extract chemicals if possible.

Government regulations these days have made it mandatory for different industries like textiles, chemicals and beverage industry to have ZLD installed so as to reduce Waste water treatment. Water recovery is the most important function of a ZLD plant. It is important to have a reliable ZLD plant to adhere to strict norms of regulations set by the government.

The ZLD processing plant constitutes physicochemical treatment, biological treatment, membrane filtration and evaporation concentration. A well designed ZLD plant handles variable volumes and speed of discharge, delivers solid waste for disposal and recovers more than 90% of liquid for further usage. Although a bit costly, it goes a long way in managing water resources wisely.

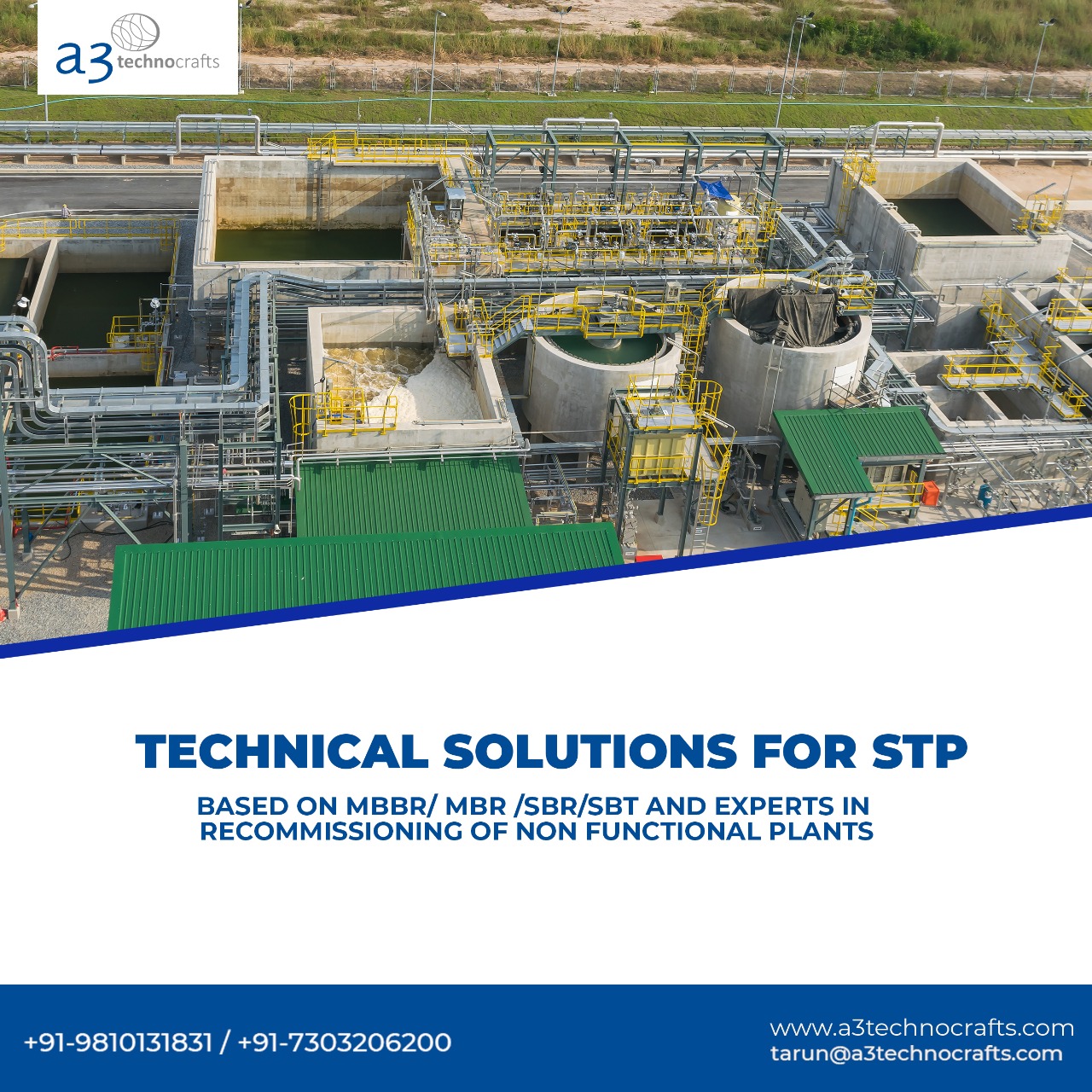

A3 is a leading system integrator offering engineering solutions for wastewater treatments. We provide customized, reliable and efficient solutions for ZLD to help you meet your corporate responsibilities. We understand your needs and come up with best possible solutions that suit your industry type. Minimize water wastage and optimize water to its maximum potential with effective ZLD plants from A3 Technocrafts.