Pump Room & Automation Solutions

The increasing population and thus the wide expansion of urban residential areas have increased the need of proper distribution of water. Establishing pumping stations is one of the most common ways of providing water from its source. In normal days there is a rapid development in urban residential area, whereas in case of water distribution system they are using conventional method, which is not automated. Water management is a matter of high priority in India and those responsible for major operations of water distribution need to be educated in this endeavor. The best way to improve the water distribution system is by using industrial PLC and SCADA system. Automation provides optimized solution to all problems of distribution of water and maintenance of the related equipment.

Hence in all projects the automation of pump station is to be carried out. This automation is done using Retrofitting with PLC and SCADA systems. Retrofitting refers to the addition of new technology or features to older systems. Since 70% of water is supplied from here, the conventional method does not provide the proper distribution of water. Hence the automation of this plant fulfills the proper distribution of water. As already there is conventional method is there for distribution, the control panels are electronic ones, the replacement of entire panels with PLC panels is time consuming and uneconomical, hence the automation of this plant with retrofitting using PLC and SCADA is feasible and economical.

Applications:

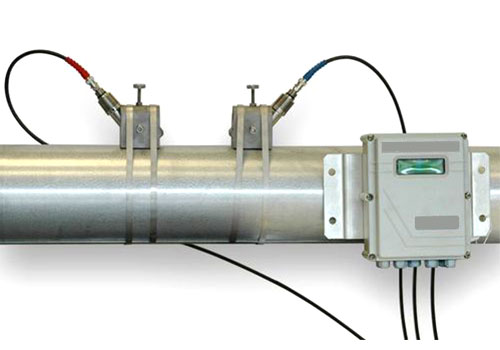

One of the applications where this model can be used is, for remote monitoring, control and automation of water pump house, clear water plants, sewage treatment plants where web/SCADA based online real time water quality, water flow, pressure, level, temperature & humidity is to be monitored. Depending upon the model & requirement the data logger/RTU can also monitor the electrical parameters of a system or pump house for remote intelligent energy/power management. Different sensors can be connected with the data loggers/RTUs to acquire data from the pump house.

Web Based Monitoring:

Monitoring & control can be done from any Explorer (IE, Google Chrome). Daily Reports can be generated of past one year data. You can monitor all your data loggers /RTUs /machines from a single window. You need not to open a separate window for each data logger. Data is refreshed automatically after every 1–15 minutes duration as per the settings. Data can be viewed in tabular form and in graphical form. Your account is protected by a username and password. SCADA application can also be downloaded from the download link on the left side menu bar. It is free with every RTU.

Remote Control Operation:

User can send commands from the web browser or SCADA application to the remote pump house to switch on/off monitors. Switching can also be done from the mobile phone. You get a response SMS for every action.

Scheduled Operations:

The pump house automation can also be done by setting the pump operation timings. The water pump can be switched on and off automatically as per the preset scheduled time. Time schedule can be set as required from the control room SCADA itself i.e. no need to go to the remote pump house.

Remote Configuration:

The data logger installed at a remote location can be configured from the control room SCADA for all settings & alerts. User can set the span, can do the calibration, specify a name for different sensors, configure the CT ratio, set errors readings. If having more than one data loggers in his/her account then each data logger can be named depending upon the location or application. Each data logger/RTU has a unique.ID.

GPRS SIM Card:

The SIM card must be GPRS enabled (VTS plan) and SMS service should be got enabled for alert text messages (SMS). Live data can be monitored on your smart mobile phone.

SMS Alert:

You can configure the unit to get Hi/Low SMS alerts. Phone book can store 5 mobile numbers to whom the alerts are to be shoot off. You can also send a request from your mobile phone to get the latest value of various parameters on your mobile.

Data Storage:

The data is stored on remote server for analysis & report generation (Optional feature). A 4GB pen drive can also be used for local level data storage.

GPS:

Unit also has provision (optional) to connect a GPS module in case you want to monitor the location of the pump house in real time. If provided, it can also work as GPS clock for real time date and time in case the RTU gets disconnected from the server. This date & time is used for putting a time stamp along with stored data on the USB.